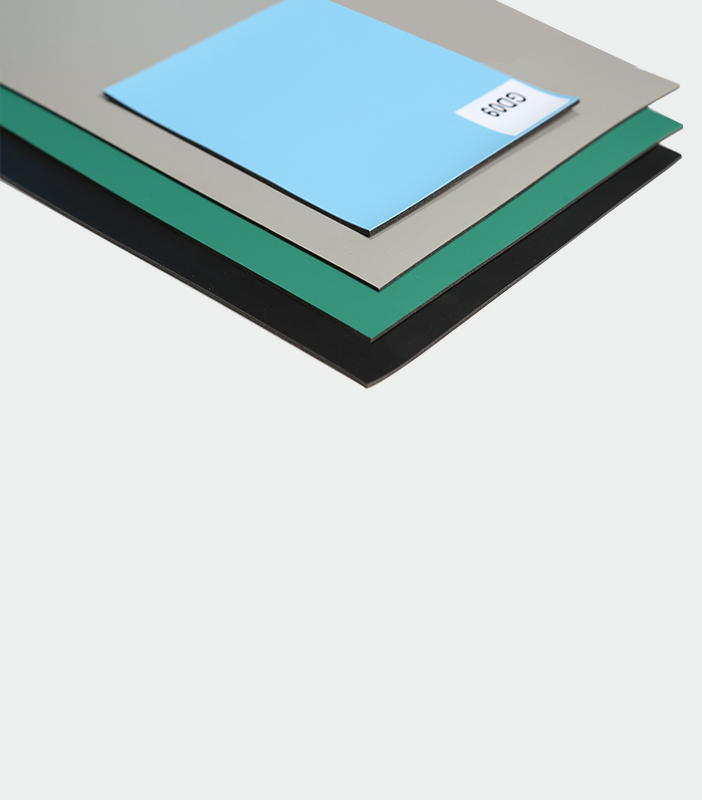

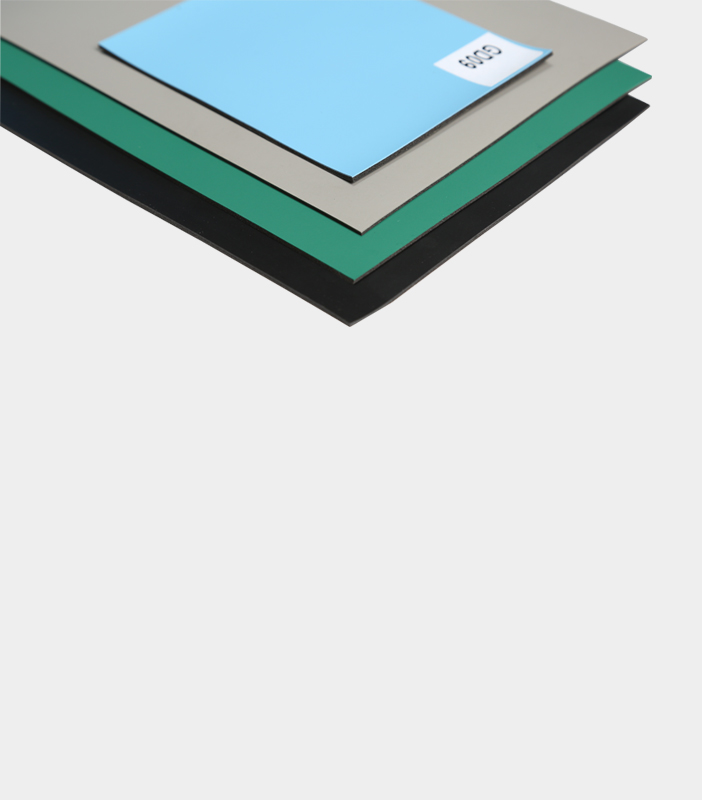

The Foam Anti-static Table Mat is a specialized product designed to provide an effective solution for controlling electrostatic discharge (ESD) in various work environments. Its material characteristics are essential for ensuring a static-free workspace.

1. Conductive Foam Material: The Foam Anti-static Table Mat is primarily constructed from a high-quality conductive foam material. This material is chosen for its excellent conductivity, which allows it to quickly and safely dissipate electrostatic charges away from sensitive electronic components and devices.

2. Comfortable Work Surface: One notable characteristic of this mat is its soft and comfortable work surface. It provides a cushioned and anti-fatigue workspace for operators who need to perform tasks for extended periods. This feature enhances user comfort and productivity.

3. Durability: Despite its soft texture, the Foam Anti-static Table Mat is designed to be highly durable. It can withstand the wear and tear associated with daily use in various industrial and laboratory settings. This durability ensures a long-lasting ESD protection solution.

4. Easy to Clean: The foam material is easy to clean and maintain, making it a practical choice for environments where cleanliness is essential. Regular cleaning helps ensure the mat’s continued effectiveness in preventing ESD events.

5. Customizable Sizes: These mats are available in various sizes to accommodate different workstations and surface areas. This customization allows users to choose the right dimensions to suit their specific needs.

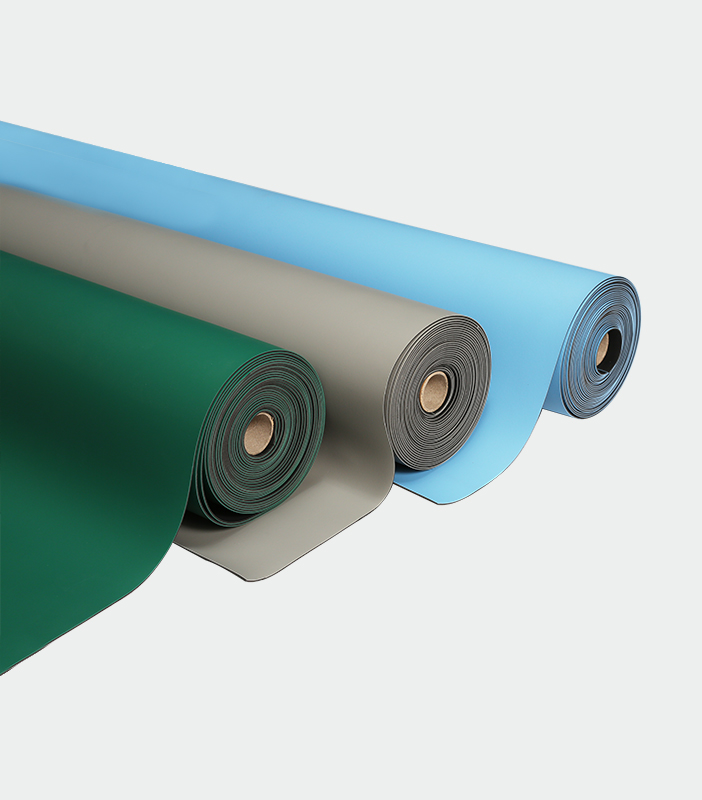

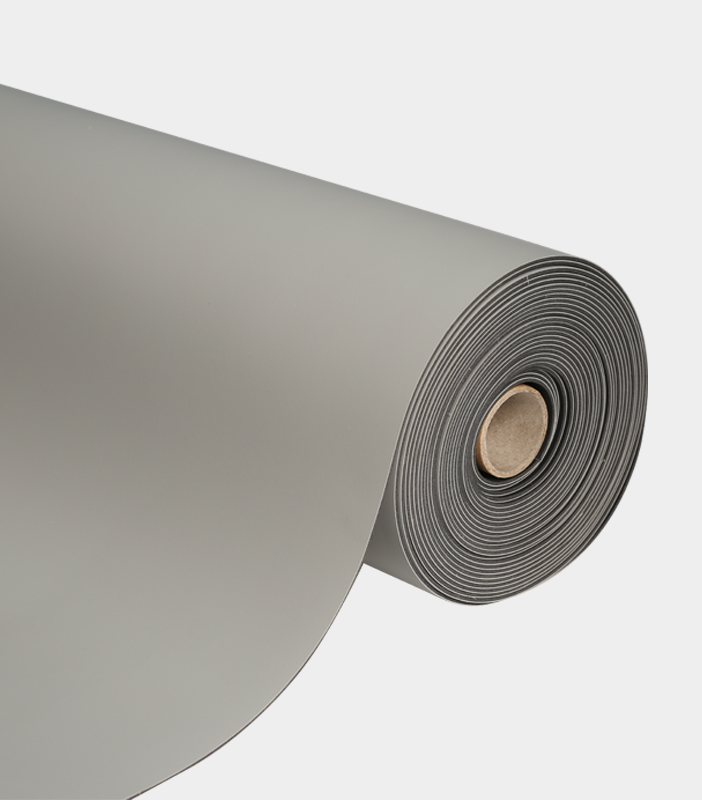

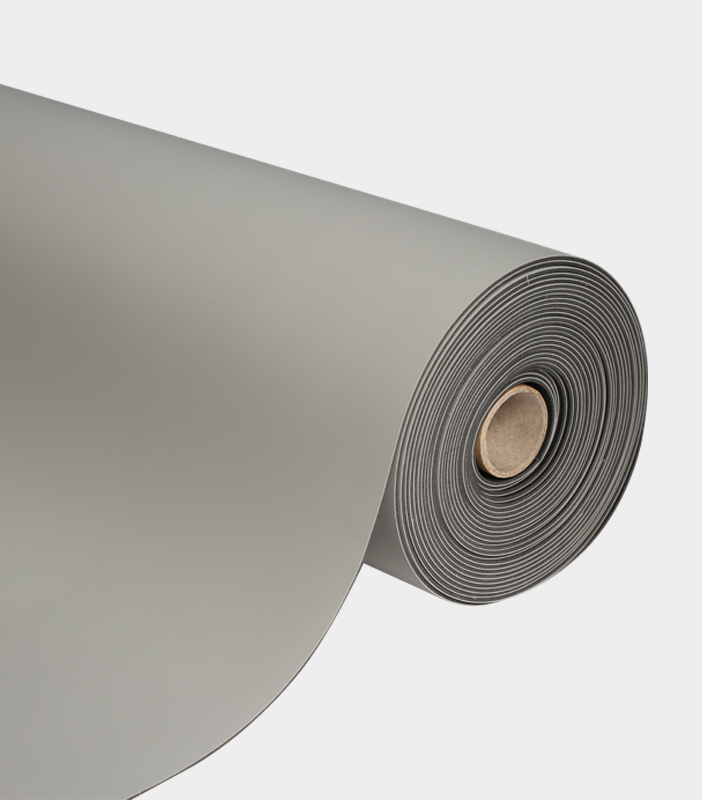

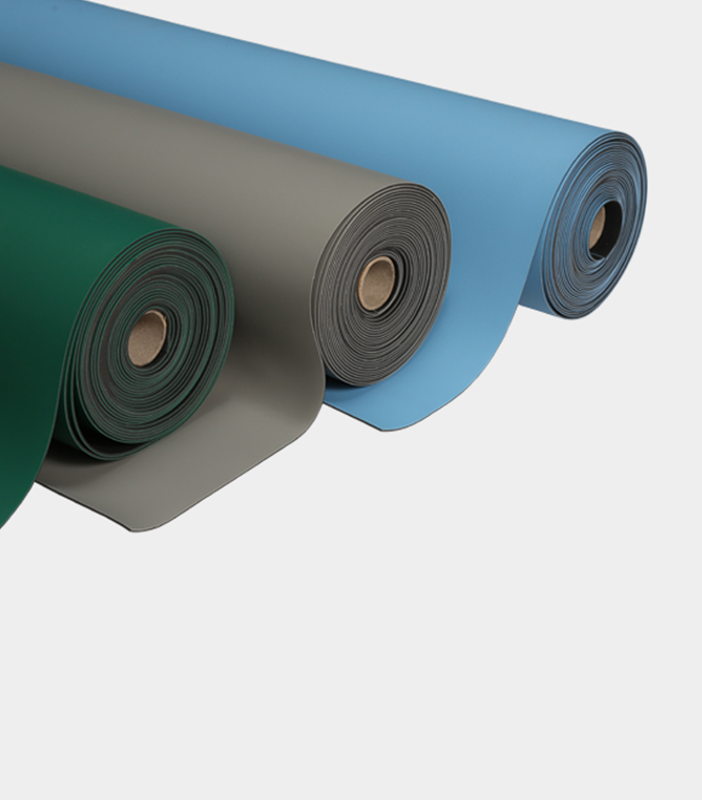

ESD Foam Mat Rolls are versatile and widely used for ESD control in various applications. The material characteristics of these rolls make them a valuable asset in protecting sensitive electronic equipment.

1. Closed-Cell Foam Structure: ESD Foam Mat Rolls are typically made from closed-cell foam, which means the foam cells are sealed and do not allow the penetration of liquids, dust, or contaminants. This closed-cell structure is essential for maintaining the mat’s ESD properties and cleanliness.

2. Effective Static Dissipation: The foam material used in these rolls is engineered to have excellent static-dissipative properties. It ensures that any static charges generated during work activities are safely and efficiently discharged through the material, preventing damage to electronic components.

3. Versatile Sizing: ESD Foam Mat Rolls come in various roll widths and lengths, offering versatility in accommodating different workspace sizes and layouts. This versatility makes them suitable for both large-scale production areas and smaller workstations.

4. Chemical Resistance: The closed-cell foam material is often resistant to a range of chemicals, ensuring that it remains functional even in environments where chemical exposure is a concern. This resistance contributes to the longevity of the mat rolls.

5. Easy Installation: ESD Foam Mat Rolls are easy to install and can be cut to size, allowing for quick customization to fit specific work areas. They can be laid out as a continuous surface or cut into smaller mats, providing flexibility in setup.

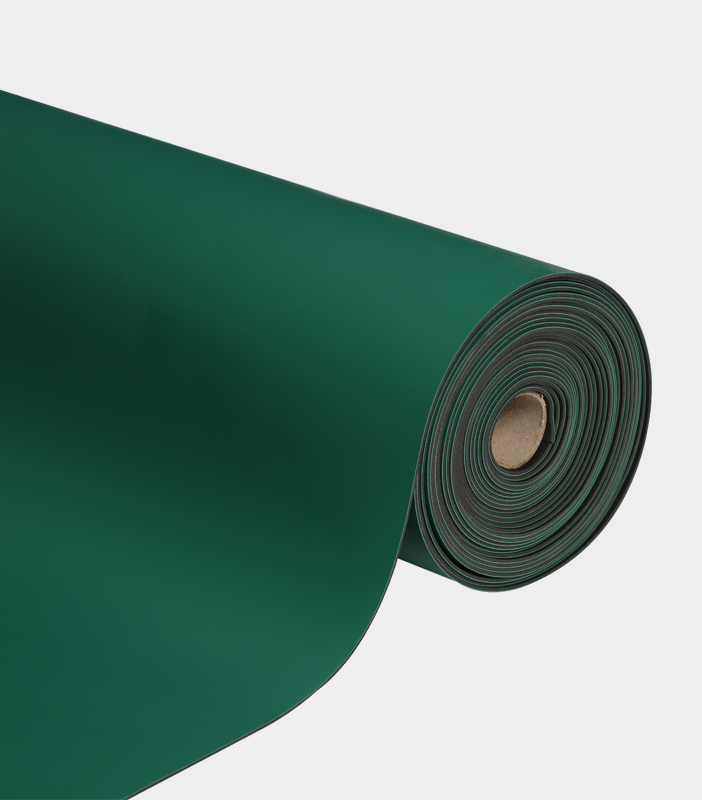

Anti-Static Foam Mats, like the previous products, serve as an effective solution for controlling static electricity in various work settings. Understanding their material characteristics is crucial for realizing their benefits.

1. Anti-Static Properties: Anti-Static Foam Mats are engineered with specialized anti-static additives incorporated into the foam material. These additives reduce the triboelectric charging of objects in contact with the mat, minimizing the risk of static discharge.

2. Economical Choice: These mats are often recognized for their cost-effectiveness. They offer reliable ESD protection at a relatively low cost compared to some other ESD control products, making them a practical choice for businesses seeking budget-friendly solutions.

3. Lightweight and Portable: The foam material used in these mats is lightweight, making them easy to transport and reposition as needed. This portability is beneficial for creating temporary ESD-safe work areas or for moving the mats between different workstations.

4. Non-Marking Surface: Anti-Static Foam Mats typically have a non-marking surface, ensuring that they won’t leave residue or marks on sensitive electronic components or devices. This feature is crucial in preventing contamination and damage.

5. Easy to Ground: These mats can be easily grounded to a suitable ground point, ensuring that any static charges generated are safely discharged. Proper grounding is essential for maintaining the mat’s anti-static effectiveness.

The Foam Anti-static Table Mats, ESD Foam Mat Rolls, and Anti-Static Foam Mats all play crucial roles in mitigating the risks associated with electrostatic discharge in workplaces.

简体中文

简体中文 English

English España

España Deutsch

Deutsch